O1 Tool Steel

O1 is an oil hardening carbon manganese tool steel, possessing excellent dimensional stability during heat treatment.

Typical applications: Press Tools, Broaches, Clipping, Marking Punches, Gauges, Jigs, Deep Drawing Dies, Slitting Cutters, Taps & Screwing Tools

A2 Tool Steel

A2 is an air hardening, cold work, tool steel. A 5% Chromium steel which provides high hardness after heat treatment with good dimensional stability. A2 delivers good toughness with medium wear resistance and is relatively easy to machine. Used in many applications which require good wear resistance as well as good toughness.

Typical Applications: blanking tools, punch dies, trim dies, forming dies, gauges, shear , blades, stamping dies.

C45U Tool Steel

C45U (1.1730) is a non-alloy cold-work tool steel that offers reasonable tensile strength. C45U can be used for components that need good machinability and wear resistance but do not justify the additional costs of an alloyed tool steel. C45U can be hardened and tempered to produce good surface hardness with moderate wear resistance properties.

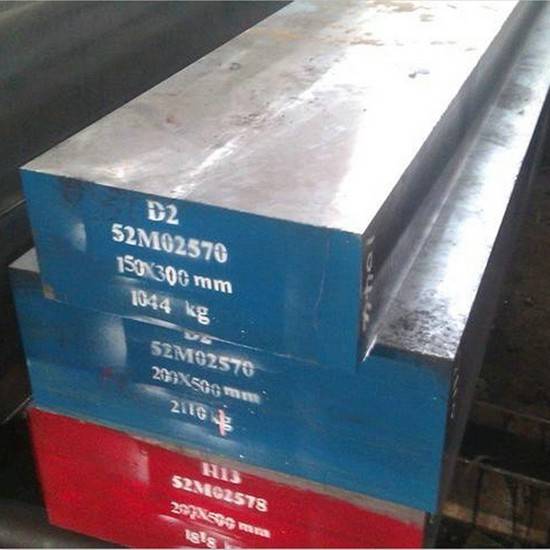

D2 Tool Steel

D2 Steel is a high carbon, high chromium cold work tool steel. Recommended for use when greater toughness is required. It offers good wear resistance and high compressive strength.

Typical applications: Press Tools (inc. heavy duty), general purpose punches and dies, crushers, gauges, swaging dies, tools requiring resistance to abrasion, blanking tools, Thread rolling, Coining, General purpose.

D3 Tool Steel

D3 Steel is a high Carbon, high chromium cold work tool steel. D3 is similar to D2 but can attain a slightly higher hardness, it displays excellent abrasion/wear resistance and has good dimensional stability and high compressive strength.

Typical Applications: Use for blanking and forming dies that require maximum resistance to abrasion. D3 is also used in forming rolls, press tools and punches.

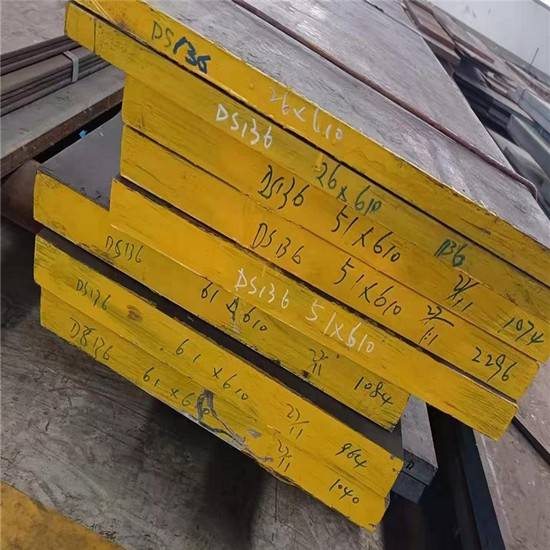

D6 Tool Steel

D6 pre-machined stock - a high carbon high chromium tool steel grade. D6 steel is an air hardening alloy tool steel with excellent resistance to wear and abrasion. Its high carbon and chromium content means it has better hardening characteristics and dimensional stability than D3.

H11 Tool Steel

H11 (1.2343) is a 5% chromium hot work tool steel. Compare to H13, H11 has less vanadium giving it higher toughness, with some reduction in wear resistance and temper resistance. H11 has excellent dimensional stability during heat treatment.

H13 Tool Steel

H13 is an air hardening chromium die steel - can be used for a range of appplications. The higher vanadium content ensures increased resistance to heat checking and all round improvement to properties at elevated temperatures. Tools may be water cooled without risk of cracking. After normal heat treatment has been carried out it is suitable for nitriding 0.30mm (0.012") deep.

Typical applications:Hot forging and pressing dies, Extrusion dies, mandrels and punches, Hot chisels, Pressure pads, Extrusion stems and rams, Blanking and bending tools, Hot heading tools, Backer blocks.

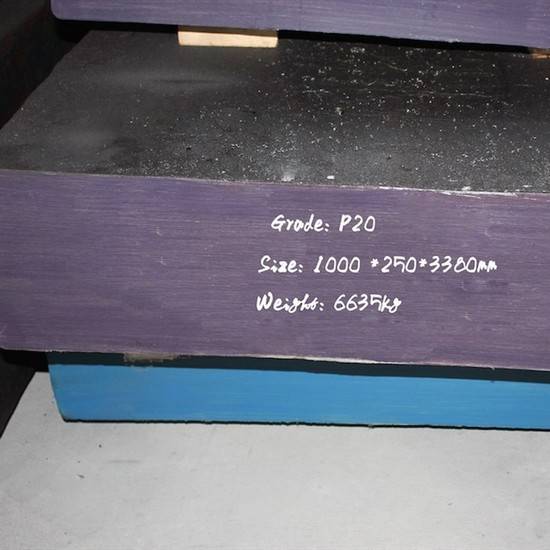

P20 Tool Steel

P20 (1.2311) Pre hardened to approximately 300 B.H (65 t.s.i) P20 requires no further heat treatment therefore avoiding risk of distortion or cracking. Although pre-hardened P20 is still capable of being machined and of giving a good polished finish.

Typical applications:Plastic moulds, backers, bolsters, die holders. Also suitable for other applications such as rails, shafts and wear strips

P20S (1.2312) Delivered pre-hardened this material is ready for use at approximately 280/325 H.B. Similar to P20 (1.2311) but with a higher sulpher content which provides much improved machinability. This grade is not suitable for polishing or other applications requiring a fine finish.

Typical applications: Suitable for large mould frames and bolsters

P20N (1.2738) Delivered pre hardened ready for use at 280/325 H.B. With added Nickel to ensure consistent hardness through large sections. Easy to polish and readyily machinable.

Typical applications: Used for quality for pressing and injection moulding tools. If the section exceeds 400mm P20 (1.2311) won't provide a consistent through hardness. Suitable for hard chrome plating and for nitriding.

69S Tool Steel

69S steel is a high carbon, high chromium cold work tool steel. Recommended for use when greater toughness is required. It offers good wear resistance and high compressive strength.

Typical applications: Press Tools (inc. heavy duty), general purpose punches and dies, crushers, gauges, swaging dies, tools requiring resistance to abrasion, blanking tools, thread rolling, coining,

9B Tool Steel

09B is an oil hardening carbon manganese tool steel, possessing excellent dimensional stability during heat treatment.

Typical applications: Press Tools, Broaches, Clipping, Marking Punches, Gauges, Jigs, Deep Drawing Dies, Slitting Cutters, Taps & Screwing Tools.

32S Tool Steel

32S is an air hardening, cold work, tool steel. A 5% Chromium steel which provides high hardness after heat treatment with good dimensional stability. A2 delivers good toughness with medium wear resistance and is relatively easy to machine. Used in many applications which require good wear resistance as well as good toughness.

Typical Applications: blanking tools, punch dies, trim dies, forming dies, gauges, shear , blades, stamping dies.

53S Tool Steel

53S is an air hardening chromium die steel equivalent to DIN 1.2344/H13. 53S provides increased resistance to heat checking and all round improvement to properties at elevated temperatures due to its higher vanadium content . This means that tools can be water cooled without risk of cracking. After normal heat treatment has been carried out it is suitable for nitriding 0.30mm (0.012") deep.

Quick Response

Quick Response

Oil & Gas

Oil & Gas

Machine Manufacturing

Machine Manufacturing

Marine Engineering

Marine Engineering

Construction Industry

Construction Industry

Chemical Industry

Chemical Industry

Power Generation

Power Generation

Product Categories

Product Categories