We are a well known worldwide supply and export rebars in following countries:,Italy, Philippines, France,Ireland, Portugal, Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Libya, Romania, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Ghana, Slovakia, Germany, Saudi Arabia, Afghanistan, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece, Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus, Finland, Gabon, Iran, Canada, Argentina, Lebanon.

Oil & Gas

Oil & Gas

Machine Manufacturing

Machine Manufacturing

Marine Engineering

Marine Engineering

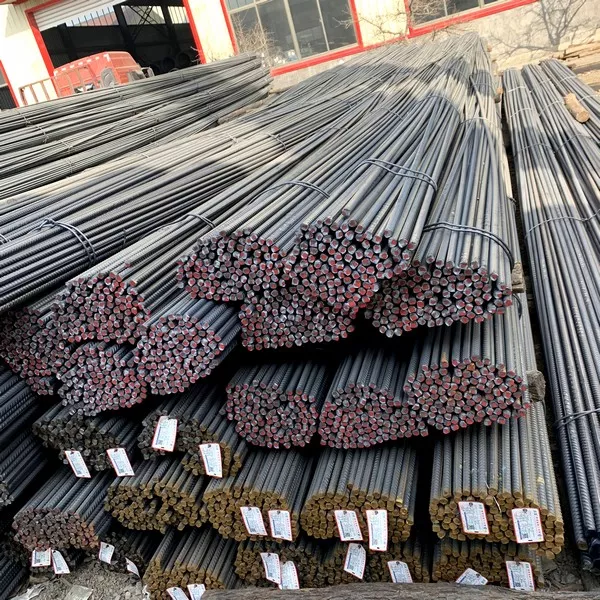

Construction Industry

Construction Industry

Chemical Industry

Chemical Industry

Power Generation

Power Generation

Product Categories

Product Categories